Extension Cords and Power Strips - Safety

Extension Cord Safety

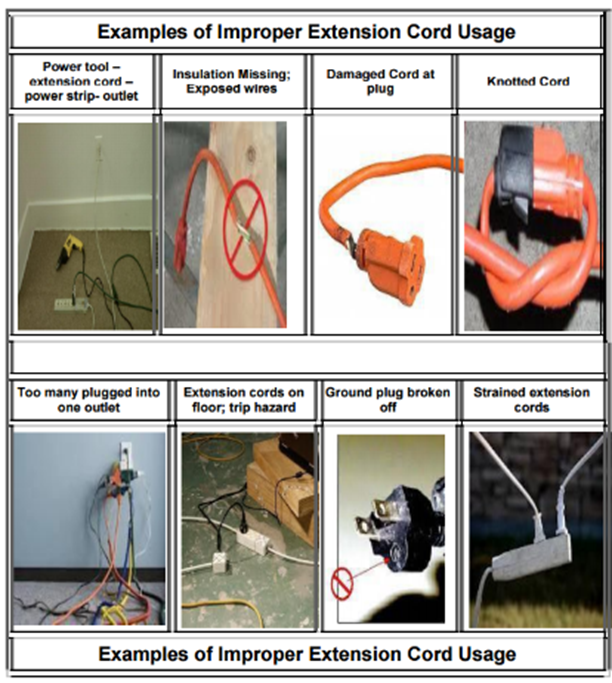

A fire hazard may result if an extension cord is overloaded or improperly used. It is against OSHA regulations which state equipment needs to be approved by a nationally recognized testing laboratory. [OSHA 29 CFR 1910.303(a)] It should also be noted that even extension cords that are approved are only for temporary wiring. They are not supposed to be used in a permanent capacity. Consideration needs to be given to the type of extension cord as well. Light-duty cords should not be used for supplying power to a number of items at once—especially those which are considered high energy.

Extension cords are sometimes used to energize power strips in locations far from outlets. Because electrical resistance increases with increased power cord length, interconnecting cords increases the total resistance and results in heat generation. This creates an additional risk of equipment failure and fire, particularly when paper and other combustible materials are in contact with the wires. Additionally, OSHA’s regulations only allow extension cords to be used as temporary wiring for up to 90 days. Any cords in place over 90 days are considered permanent wiring. Unfortunately, once in place, extension cords tend to become permanent wiring and a fire hazard

OSHA (Occupational Safety and Health Administration) provides guidelines and regulations on the safe use of extension cords in the workplace. Some key requirements include:

- Extension cords should only be used temporarily, not as a permanent power source.

- Cords should be approved for the specific application and be in good condition, with no cuts or frayed wires.

- Cords should be matched to the equipment being powered, with the correct amperage and voltage ratings.

- Multiple cords should not be connected to make longer lengths, and cords should not be used as substitute for permanent wiring.

- Cords should not be run through doorways, windows, or walls, and should be protected from damage from foot traffic or equipment.

- Outlets should not be overloaded, and multiple plugs should not be used in the same outlet.

- Wet or damp locations should not be used with electrical equipment, including extension cords.

It is important to note that OSHA regulations apply to the workplace, not necessarily to residential or personal use of extension cords. However, following these guidelines can help ensure safe use in any setting.

Power Strip Safety

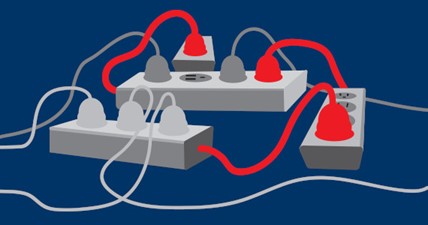

The supply of readily available electrical outlets is inadequate in some older buildings. Extension cords or surge protected power strips are often interconnected, or “daisy chained,” to readily provide more outlets and/or to reach greater distances. Another common solution that is often used is to create a “mixed daisy chain,” by interconnecting several extension cords and surge protectors or power strips in a series. However, interconnecting these devices is a violation of Occupational Safety and Health Administration (OSHA) regulations and the National Electrical Code because doing so can cause them to become overloaded, which could lead to their failure and a possible fire

Daisy Chaining

Daisy chains and mixed daisy chains constitute some of the most common violations identified during Naval Occupational Safety and Health (NAVOSH) inspections.

This is a term that refers to power strips and/or extension cords being plugged into other power strips and/or extension cords. Daisy chaining usually occurs when there are not enough established outlets to meet electrical needs.

Problems

OSHA regulations require that conductors and electrical equipment be used in accordance with the conditions under which they are approved by a recognized testing organization (29 CFR 1910.303(a)). Most power strips or surge protectors are approved for providing power to a maximum of four or six individual items; however, when multiple power strips are interconnected, the one directly connected to the building outlet is often supplying power to far more outlets than the approved. This electrical current overload can result in a fire or can cause a circuit breaker to trip, de-energizing computers and other equipment throughout the area that are connected to the surge protector

.

Solutions

Several safe solutions exist. In many cases, a power strip energized by an extension cord or another power strip can simply be replaced by a power strip with a power cord of adequate length to reach an outlet. Alternatively, desks and associated equipment may be moved so they are closer to existing outlets. Other times, use of a power strip that is better able to accommodate bulkier transformer plugs solves the problem.

Several factors should be considered when selecting an appropriate surge protector. Since models vary in the amount of current that they are rated to safely carry, it is important to consider the amperage requirements of the devices to be energized. Models vary in length of power cord, typically ranging from three to 15 feet. Choose one with a length that is most appropriate for reaching the intended room outlet. Avoid having excess cord that could get in the way and cause a hazard. Ensure that the surge protector is set on its base. Some have swivel plugs which make them easier to connect to the outlet, and helps to protect the plug and cord from damage. Check each surge protector to make sure it is in good condition for use

Only power strips equipped with internal fuses are acceptable as permanent wiring. Those lacking these fuses are equivalent to extension cords, and therefore may not be used as permanent wiring. When a power strip is installed, care must be taken to ensure that it is not suspended in midair by its power cord or cords plugged into it, resulting in excessive stress on electrical connections.

When there are not enough outlets to supply occupants’ needs, one solution is to request the installation of additional wall or floor outlets. Their placement should avoid any need to run any wires across walkways, where they can create tripping hazards. Consideration can also be given to the merits of installing modular furniture that provides multiple outlets at each workstation. Interconnected modular furniture units are energized by the building’s electrical supply through a single, large power cord, or “whip,” providing ample power to all served workstations.

Fast Facts

- All conductors and equipment must be approved by an OSHA Nationally Recognized Testing Laboratory (NRTL) (29 CFR §1910.303(a).

- OSHA’s electrical standards require that listed or labeled equipment be used or installed in accordance with any instructions included in the listing or labeling by the manufacturer (29 CFR §1910.303(b)(2)).

- OSHA’s electrical standards require that outlet devices have an ampere current rating not less than the current load to be served (29 CFR §1910.304(b)(2)).

- The National Electrical Code and OSHA do not permit extension cords to be used for permanent wiring.