Scientists in lab coats build tunnels through quantum space. They connect microscopic tubes and build structures that sense defects, carry information and deliver energy one molecule at a time. As fantastic as it may seem, researchers at the Naval Postgraduate School’s (NPS) newest academic center, the Center for Materials Research, have accomplished all of this and more.

The Navy has been thinking about materials research for a very long time. It is a discipline intrinsically linked to maritime history. Ships, and the sailors that travel upon them, rely upon materials research to survive the ravages of war, seawater and weather.

NPS’ Center for Materials Research (CMR) was born out of collaborative measures between faculty and administrators to meet the materials challenges of a modern naval force.

“We envisioned a center where we could bring together dynamic, new talent in the materials research field and partner them with seasoned researchers,” said Dr. Leonard A. Ferrari, ?NPS Executive Vice President and Provost. “The creation of this competitive, new center demonstrates NPS’ on-going commitment to defense-centered, scientific research in a time when demand for innovative Navy materials solutions has never been greater.”

Distinguished Professor Emeritus Dr. Terry R. McNelley and Distinguished Professor Dr. Nancy Haegel spearheaded an effort to bring together top young scholars from across the academic spectrum to create the CMR.

“The need for sensors and new materials is very important to the fleet,” said Haegel. “The Navy’s needs drove our desire to hire new researchers from a variety of disciplines that could work across the varied fields that encompass materials research.”

“The emergence of the center has enabled us to work across department boundaries and we have managed to strengthen materials activities here at NPS,“ said McNelley. “We no longer work in isolation, we have found ways to pull together … You could say that the sum of what we have done is much greater than its individual parts.”

Those “individual parts” include a host of new faculty recruited to reinvigorate materials research at NPS.

“The reason that the CMR has coalesced in the manner that it has, is due to the new people that we have brought in. They have begun their own research which has led to new ideas and interests beings explored,” said McNelley.

Increased coordination and new minds became necessary as the materials research field advanced at NPS. Modern materials research includes a mind-numbing host of academic specialties – metallurgy, corrosion analysis, nanomaterials, new materials, composites and physics to name a few.

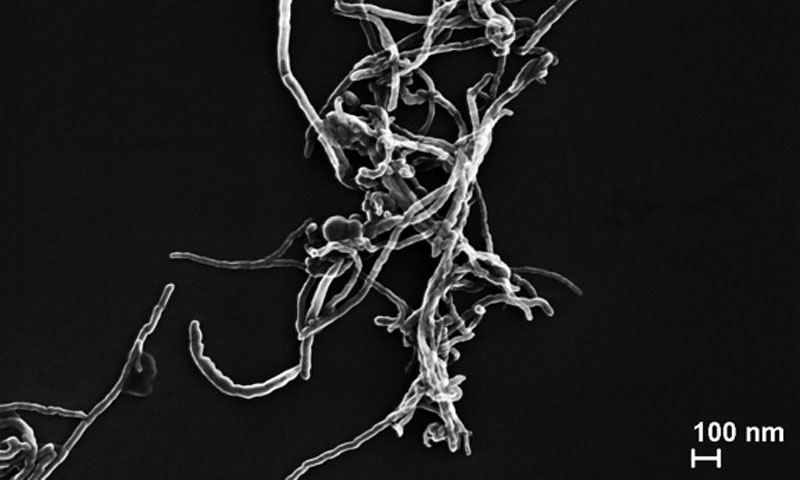

In microscopic detail, nanotubes grown in NPS’ Center for Materials Research lab are being used in the study of several diverse projects, from monitoring composite ship patches to the development of miniature satellite propellants.

“In the field today, there is a lot overlap between the disciplines,” said Haegel. “Materials, physics, and engineering are now interconnected, especially now that we are working with materials at the nanolevel.”

Distinguished Professor Dr. Young Kwon of mechanical and aerospace engineering, CMR director, works with the center on nanomaterial engineering. His work demonstrates the manner in which the materials sciences have evolved in recent years.

“Sometimes we are looking at materials as small as a few atoms,” said Kwon. “Materials behave very differently at the nanolevel when compared to the same materials on the larger scale ... We are synthesizing nanomaterials and looking for new applications.”

Applications that utilize what is seemingly the stuff of science fiction, nanotubes built at the molecular level, microscopic sensors and even nanonengineered engines. NPS researchers insist that none of these advances would have been possible without a cross-disciplinary approach to materials study.

And the approach has already begun to pay dividends. The application and study of composite materials, has been combined with nanotubes research to repair cracks on ship structures and monitor the efficacy of composite patches.

“One of the many applications of composite materials is the use of composite patches on aluminum ships. Composite patching is less expensive and more effective than having to re-weld materials in dry-docks,” said Young. “Composite patches are more effective, but how do you know what is happening under your patch? You need to be able to monitor a crack once its been covered.”

In order to see what’s happening, Kwon and his colleagues have developed a method of using nanotubes beneath patches to monitor patched cracks. If the crack widens, the nanotube breaks, and the resulting loss of conductivity can be measured and used to monitor hull integrity beneath a composite patch.

But composite material researchers are not just patching ships. They are also working to create new materials for ships, materials that will allow engineers to build ships from lighter, stronger materials. These innovations promise safer, more fuel-efficient vessels for an increasingly, green fleet.“We want to make fast ships … composite materials are light and corrosion resistant, they decrease payload and fuel consumption,” said Kwon.

Another interesting application of nanotechnology at NPS involves the development and use of sensors built at the molecular level.

Assistant Professor of physics, Dr. Joe Hooper of Altanta, Ga., specializes in ‘shock physics.’ Hooper is part of the ‘new blood’ recruited by the CMR. One of his projects involves the placement of microscopic sensors into the composite materials that compose the bodies of warheads. If successful, Hooper will be able to look inside a warhead as it detonates.

Center for Materials Research faculty, from left to right, Research Professor Sarath Menon, Associate Professor Claudia Luhrs, Assistant Professor Sebastian Osswald, Associate Professor Luke Brewer, Assistant Professor Dragoslav Grbovic, Center Director Distinguished Professor Young Kwon, and Professor John Phillips.

Assistant Professor of physics and mechanical and aerospace engineering, Dr. Sebastian Osswald, and his research group are utilizing nanostructures to enhance the performance of armoring materials, energy storage devices, and sensors. They are even developing “ion thrusters,” miniature engines that may one-day power small spacecraft.

“We are developing a novel carbon nanotube field ionization engine that will, for the first time, allow for the design of scalable micro-ion thrusters, bringing us a step closer to the realization of nano and picosatellite technologies,” said Osswald.

Dr. Claudia Luhrs is working to build lightweight metals that could potentially protect U.S. service members in the field from the shock forces generated by explosives and other weapons. She came to NPS after completing work at Intel and Toyota North America and holds five patents for innovative energy storage technologies.

Assistant professor Dr. Dragoslav Grbovic is engineering micro-electromechanical systems. These micro-sized machines, the width of a human hair, will harvest wasted energy for use in other applications. He is also developing micro-sized sensors and actuators for use in infrared and THZ imaging.

Oswald, Hooper and associate professor Dr. Luke Brewer are looking into the use of “nanodiamond” – the hardest material found in nature – to reinforce armor and harden structures.

Impressive as all of this may seem, it is only the tip of the iceberg. Work at the CMR has really just begun.

“We are already showing promise, we have good people, doing good research and we are receiving excellent sponsorship as we seek solutions to the Navy’s most pressing material needs,” said McNelley.