As an institution renowned for innovation efforts grounded in education and research, the Naval Postgraduate School (NPS) has often been called upon to tackle some of the most difficult technological challenges facing the Navy and the nation.

Such a challenge emerged in 2020, when NASA charged NPS and two other research teams with solving a critical barrier facing the development of electric aircraft propulsion (EAP): the creation of a circuit breaker that could support large electric platforms running on direct current (DC) electricity. Thanks to the efforts of a diverse team of faculty and students, as well as several Navy and academic research partners, NPS delivered an innovative working prototype.

This past March, the successful test of the “Navy High Speed Solid-State Fault Management System for Electric Aircraft Propulsion” confirmed the breakthrough results. The NPS-led design was able to provide a viable DC circuit breaker to NASA, pushing the project development forward to Level 6 on the Technology Readiness Level scale – a 9-level measurement system used to assess the maturity of a particular technology.

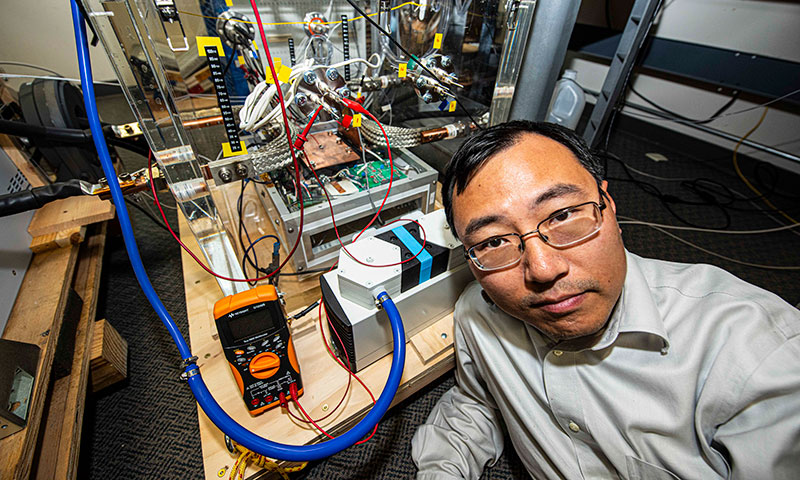

The effort to research and design the DC circuit breaker for EAP was led by Dr. Di Zhang, NPS Associate Professor of Electrical and Computer Engineering, along with a team of NPS students. Zhang, who came to NPS in 2019 after working on electric power converter designs with General Electric’s Global Research Center, is widely considered one of the nation’s leading experts on large electric vehicles.

As a result of his team’s work, Zhang was awarded a $750,000 research grant by NASA to continue his research with a goal to refine the weight and performance of the team’s initial breaker design.

The breakthrough achieved at NPS could be a critical step in the development of EAP, one of many emerging technologies receiving increased attention due to the emphasis placed by the Secretary of the Navy, Carlos Del Toro, on accelerating innovation throughout the Department of the Navy.

“We are indeed in an innovation race — and it is one we must win,” said Del Toro during remarks at the Naval Research Laboratory in Washington, D.C., on Sept. 28. “Innovation must permeate every aspect of our Department’s approach to the delivery of the technologies and capabilities at a speed and scale necessary for our Navy and Marine Corps to confront the challenges of today and the future.”

NPS will play a significant role in supporting the development of EAP technology and other relevant innovation efforts following the establishment of the Naval Innovation Center (NIC) at NPS. First announced in December 2022, the NIC will leverage NPS education and research to drive “ideas to impact,” bringing research concepts out of the lab and into the field faster by empowering students, faculty and partners across the entire Naval Research & Development Establishment (NR&DE) to work with the naval innovation ecosystem and industry.

Accelerated innovation for technologies such as EAP is also facilitated through the Secretary of the Navy’s “Climate Action 2030” policy, which prioritizes the development of systems that are not dependent on fossil fuels, expanding the use of renewable energy and electric propulsion.

In addition to supporting Climate Action 2030 and similar policy goals, EAP can also enable numerous new design freedoms and functions, leading to lower energy consumption and higher propulsion efficiency. And, of course, the noise signature of combustion engines could be all but eliminated utilizing EAP, enhancing stealth capabilities of future systems.

“Electric propulsion technology is crucial for future Navy capabilities, offering enhanced design flexibility, supporting power-intensive advanced systems, and ensuring stealth, efficiency, and adaptability in evolving naval environments,” said Zhang. “The technology's integration also paves the way for the adoption of emerging energy sources, solidifying the Navy's technological edge.”

Zhang and his NPS student team were joined in their research efforts by partners from Virginia Tech, Clemson University and the University of Connecticut, and received engineering support from Naval Air Systems Command (NAVAIR) in China Lake, Calif., and the Naval Surface Warfare Center (NSWC) Philadelphia division.

According to Zhang, one of the fundamental questions when looking at utilizing electric power is the distinction between products that run on direct current and alternating current (AC).

“A hundred years ago, Nikola Tesla and Thomas Edison had a battle over the advantages of AC versus DC electric power. Tesla won, and now much of what we use and see is running on AC power,” said Zhang.

There are certain advantages to using AC electricity, he says. AC generators are the primary source of electric power, which are driven by steam, nuclear, or other power sources. AC can be transmitted across great distances and is also easily changed to different voltage levels through the use of transformers that can step voltage up and down. As its name implies, AC has an alternating current that runs in a sinusoidal pattern; this makes AC electricity relatively safe and easy to interrupt with a circuit breaker as the waveform naturally crosses zero.

Direct current has its own advantages that are rising in importance as technology looks to the future. DC systems require less cabling and can be smaller and lighter than AC systems, as well as more power efficient. Clean sources of energy – like wind and solar – store power in photovoltaic grids and batteries which are inherently DC compatible. Electric cars that use DC power are also able to use regenerative braking to return energy to their batteries, and they are run in a compact space that does not require long distance transmission.

“The trend we’re seeing in energy industries and in electric vehicles is this switch to DC, and that’s why it is so important to look towards this electric aircraft design,” explained Zhang. “With DC, we can make a design lighter and smaller with the same power which is critical for aviation and Navy applications. The target for this DC breaker design is to get the same amount of power while cutting the weight to one tenth of what’s been developed.”

One thing that doesn’t get smaller and lighter with DC systems is the circuit breaker. The challenge that NASA posed to NPS was to create a circuit breaker that could shut down an electric aircraft running at maximum power in a safe, simple – and size-efficient – way.

“Think of electricity flowing like water through a pipe. A circuit breaker is the tool you need to shut that water off. With DC, high amounts of current and voltage equate to a huge flow of water that is hard to shut down quickly,” explained U.S. Marine Corps Capt. Michael Smith, an NPS electrical engineering graduate. “That quick change from a high to low voltage, or high to low current, creates an electromagnetic field that can interfere with other electric systems.”

Capt. Smith is one of five NPS students who worked on the project with Zhang. Since his graduation in September 2022, he now applies his degree as an Expeditionary Energy Officer for the Marines. His master’s thesis focused on testing circuit boards to ensure they could withstand the electromagnetic interference of a large-scale DC circuit breaker, and he was able to successfully identify manufactured circuit boards that would function under the required conditions.

“The trick to reaching industry standards is in the balance,” said Zhang. “You need to design something new, but not too new or it is unproven and risky. You cannot only be innovative; you must also be practical. So, we had three years during a global pandemic, which hindered manufacturing and access to technology, to produce a result that is as safe and simple as possible.”

In spite of those challenges, the team was able to successfully meet the deadline. While Zhang is pleased with the achievement of his students and the positive feedback from NASA, he is far from done with this research.

“I’m very proud of the students that I’ve worked with who have shown great ability with hands-on research,” said Zhang. “I’m also proud of my team and colleagues here at NPS who have such strong industry experience and perspective towards electrical engineering. It’s with this perspective that we’re able to deliver something so practical, useful, and impactful.”

NPS Vice Provost for Research Dr. Kevin Smith complimented Zhang and his research team, noting the achievement as an exemplar of how basic and applied research at NPS leads to relevant technology solutions.

“Di Zhang’s accomplishment is a great example of how our faculty lead interdisciplinary research at NPS, leveraging our students’ operational insight and our innovation ecosystem of academic and industry partners to solve problems and drive concepts to capability,” said Dr. Smith.